One Ocean Data Platform for the Whole Lifecycle of a Wind Farm

Introduction Wind farm projects, often stretching over 60, 100, and more square kilometers in ocean areas, are designed for 30 years of operations....

Waiting is a significant source of waste in data workflows. Traditionally, data delivery using physical hard drives has been time-consuming, unsafe, and insecure. However, with a centralized data storage and a web-based platform like TrueOcean MDP, waiting times can be eliminated. Collaborators can access data instantly, either by being invited to projects or by sharing data via different protocols such as SFTP or RSynC. Special software requirements are no longer a barrier, as data sets can be directly downloaded from the centralized data space. Delivery to customers can be streamlined through download links or web mapping services (WMS/WMF), reducing waiting times and improving overall efficiency.

Insufficient computing power and limited resources can impede data processing, especially when dealing with large data sets. A marine data platform with cloud infrastructure overcomes this limitation by providing compute resources on demand. With virtually infinite scalability, processing tasks are no longer constrained by local resources. This eliminates the waiting time associated with resource limitations and allows for parallel processing, enhancing productivity and reducing overall project timelines.

Manual process steps are prone to errors and can be time-consuming. By leveraging a marine data platform, many data processing steps can be automated. Uploaded data can be processed on the fly, enabling real-time calculations of quality scores and other quality metrics. Automation not only saves time but also improves accuracy and consistency. By reducing manual intervention, the platform eliminates waste and ensures standardized data processing throughout the workflow.

The principles of lean management and the elimination of waste (Muda), which aim to eliminate waste and optimize efficiency, find a natural fit in the context of marine data platforms. By centralizing data storage, the platform minimizes waste related to multiple data sources and excessive data duplication. Waiting times are reduced or eliminated, defects in data sets are mitigated through automated quality control (QC), and the overproduction of redundant data collection or results generation is prevented. Moreover, transparency and traceability within the platform enable better control over data manipulation, reducing the risk of over-processing.

The digitalization and automation of data workflows through marine data platforms like the TrueOcean MDP offer substantial benefits to the offshore wind industry. By eliminating waste and streamlining processes, these platforms enhance productivity, reduce costs, and improve the customer experience. The elimination of waiting times, provision of compute resources on demand, and automation of data processing contribute to increased process efficiency and standardized workflows. By adopting lean management principles and leveraging a marine data platform, companies in the offshore wind industry can achieve tangible improvements in their data process flows, leading to higher profitability and a greater focus on value creation for their customers. Embracing this digital transformation is a proven strategy to thrive in the evolving landscape of big data processing and collaboration.

Introduction Wind farm projects, often stretching over 60, 100, and more square kilometers in ocean areas, are designed for 30 years of operations....

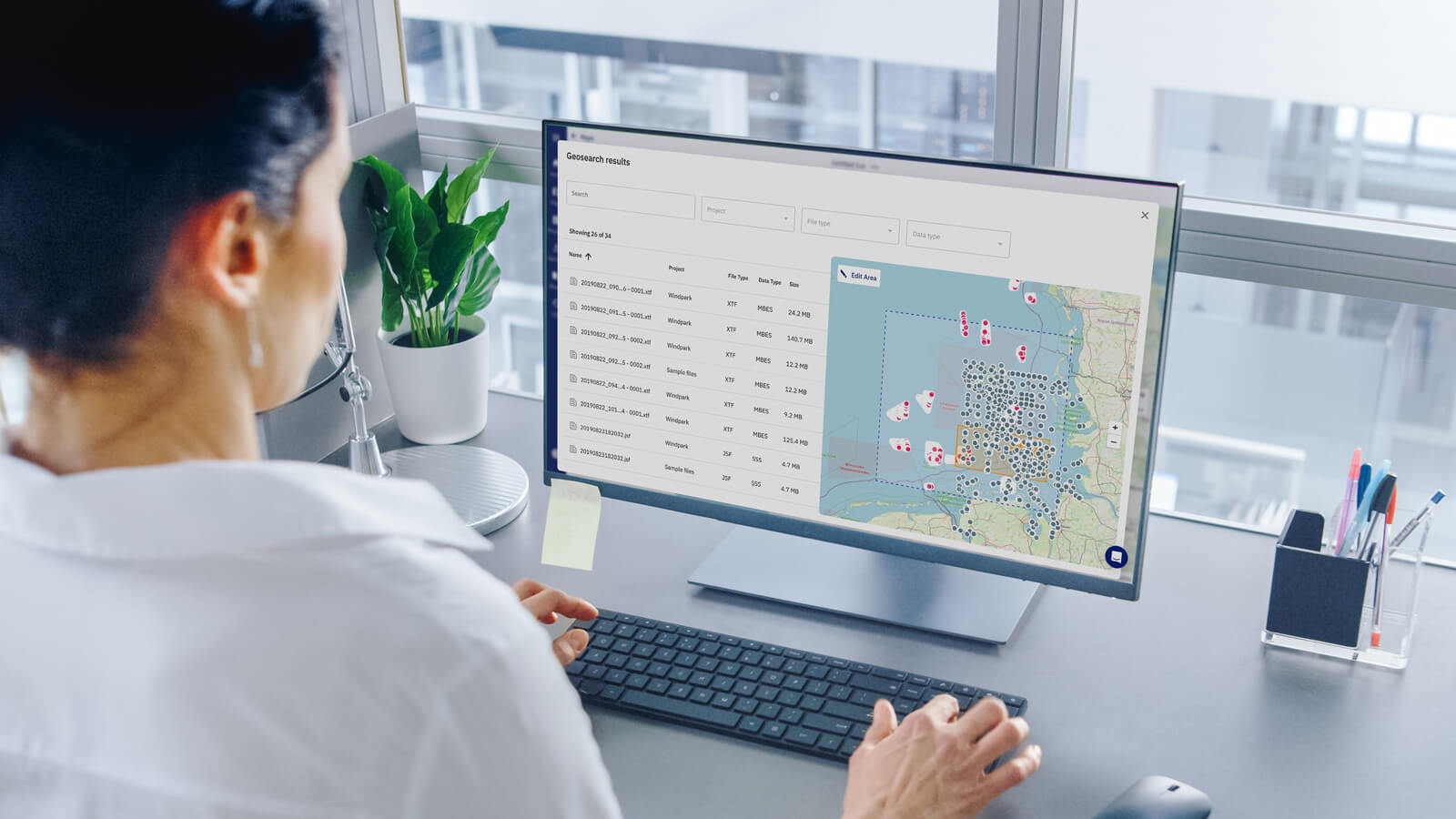

In today's fast-paced ocean industry, the ability to efficiently manage and locate hydrographic survey and underwater inspection data is crucial. The...

WindEnergy 2024 in Hamburg has come to a close, and what an incredible few days it’s been for north.io! We took this fantastic opportunity to...

In the fast-paced world of offshore energy, "the need for cost efficiency, increasing time pressure and the availability of experts is what keeps...