Smarter Offshore Survey Planning with TrackPlanner

The Problem: Inefficiencies in Line Planning Are Costing You In offshore surveys, time really is money. Vessel operation costs can easily exceed...

The High Cost of Hindsight in Offshore Surveys

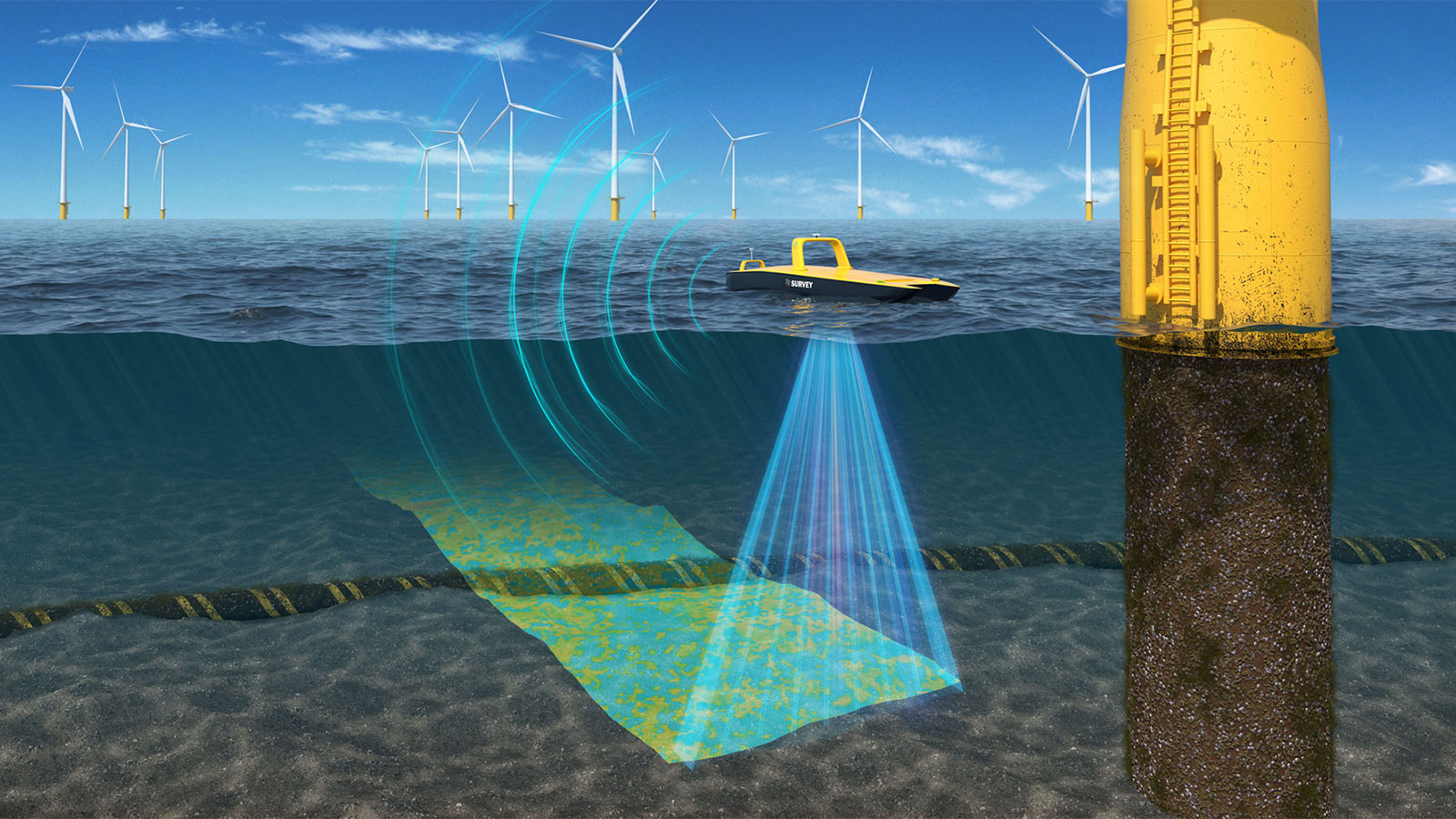

In the demanding world of offshore operations, precision is paramount. Whether you're an offshore survey company mapping the seabed, a utility operator managing subsea infrastructure, or a Transmission System Operator (TSO) overseeing critical underwater cables, accurate and complete data is the bedrock of success. Yet, a persistent and costly challenge plagues the industry: data gaps in survey lines.

Imagine this scenario: A survey vessel, equipped with state-of-the-art sensors, meticulously traverses its designated area. Days, or even weeks, later – long after the vessel has moved on to its next assignment, perhaps hundreds of miles away – the collected data is finally processed. It's then that the grim reality hits: there are "holes" in the survey lines. Critical sections of the seabed remain unmapped, or data quality issues render portions unusable. This isn’t just inconvenient – it comes with serious financial consequences.

The need to re-survey these missing sections, often referred to as infill surveys, triggers a cascade of exorbitant costs. Mobilizing a specialized survey vessel, along with its highly skilled crew and advanced equipment, commands daily rates that can easily run into the tens of thousands, if not hundreds of thousands, of Euros. Furthermore, the urgency of such re-mobilization often means paying premium rates, and even then, vessel availability can be a significant hurdle. The delay impacts project timelines, jeopardizes contractual obligations, and can lead to substantial penalties. In essence, a small data gap can quickly balloon into a multi-million Euro problem.

The Near Real-Time Revolution: From Reactive to Proactive

What if you could identify and address these data gaps the moment they occur, while the survey vessel is still on-site? This is the transformative power of real-time underwater sensor data processing and immediate quality control (QC). By shifting from a reactive, post-processing model to a proactive, near real-time approach, offshore stakeholders can unlock unprecedented efficiency and achieve massive cost savings.

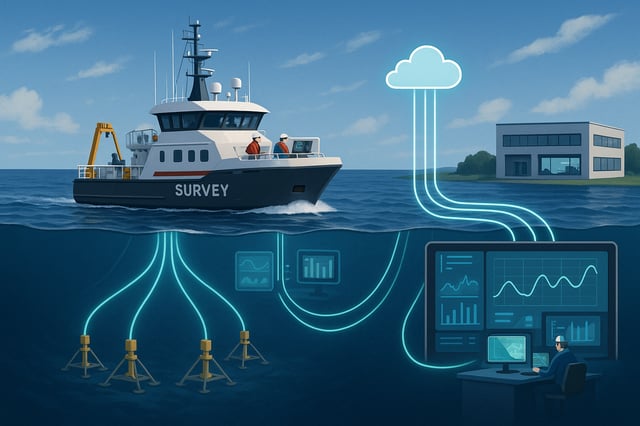

North.io's innovative approach, leveraging a "ping-to-cloud" methodology, enables data to be streamed directly from the underwater sensors to an onshore processing and analysis hub. This means that instead of waiting for days or weeks, data quality checks and gap analyses can be performed almost instantaneously by experts located remotely. This immediate feedback loop is a game-changer.

What's In It For You?

For every stakeholder in the offshore industry, the advantages of near real-time data processing translate directly into tangible benefits:

For Offshore Survey Companies: Maximize Efficiency, Minimize Rework

Your primary goal is to deliver accurate and complete survey data on time and within budget. Real-time QC allows your onshore team to monitor data acquisition as it happens. If a data gap is detected, or if the quality falls below acceptable thresholds, the vessel can be immediately notified to re-acquire the necessary data while still in the survey area. This eliminates the need for costly re-mobilization, saving you hundreds of thousands of Euros per incident. It also significantly reduces project timelines, allowing you to take on more projects and improve your profitability.

For Utility Operators & TSOs: Enhanced Asset Integrity and Risk Mitigation

Managing critical subsea infrastructure, such as power cables or pipelines, requires continuous monitoring and precise data for maintenance and integrity assessments. Near real-time data processing provides immediate insight into the condition of your assets and their surrounding environment. Early detection of potential issues, such as seabed erosion near a cable or changes in sediment thickness and cover, allows for proactive intervention, preventing costly failures and ensuring uninterrupted service. This proactive approach mitigates risks, enhances operational safety, and extends the lifespan of your valuable assets.

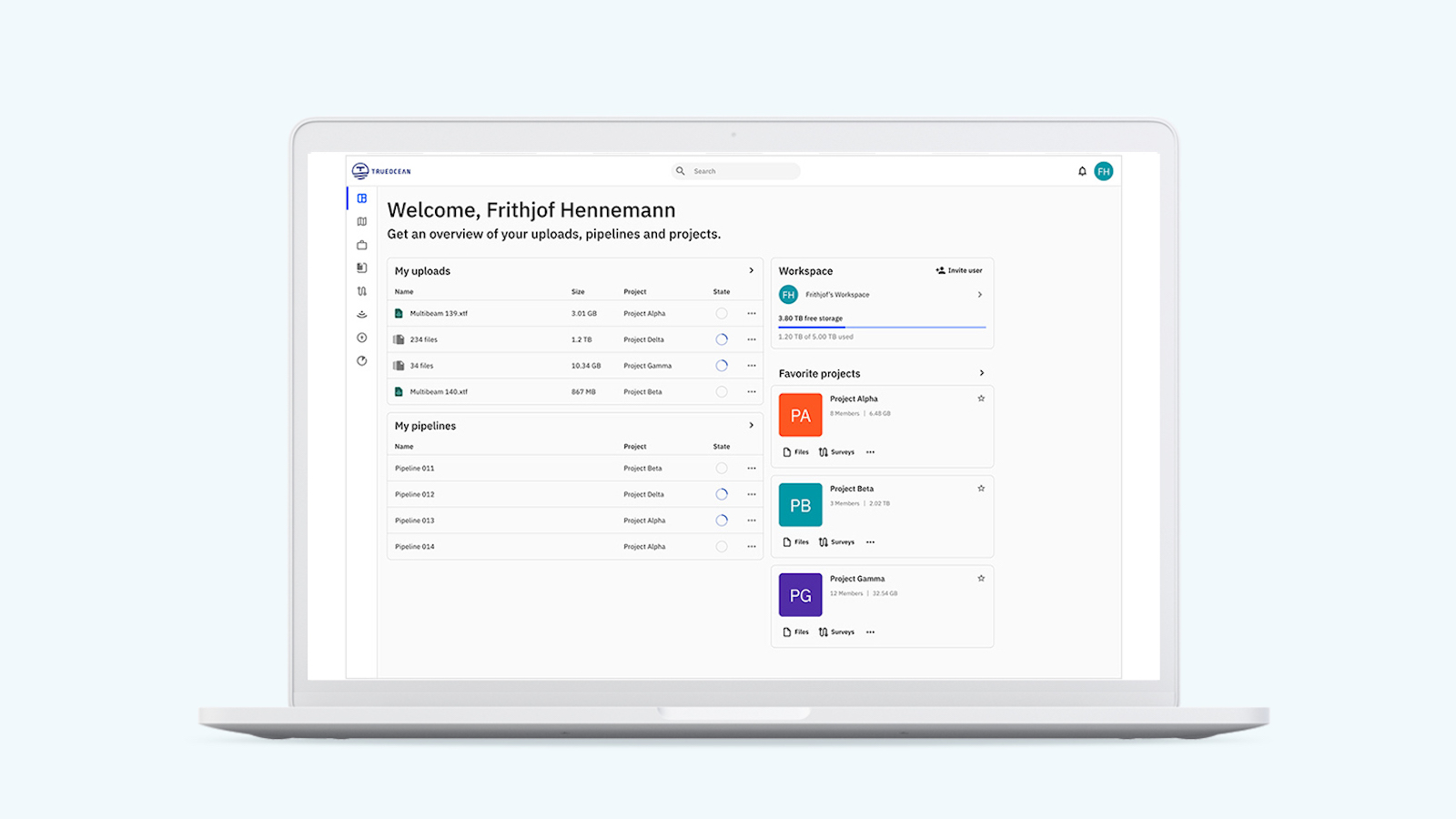

The Power of Immediate Quality Control

Immediate, automated quality control from onshore is a cornerstone of the near real-time data revolution. Traditionally, QC has been conducted onboard the survey vessel—an approach that enables early identification of issues shortly after acquisition, often reducing overall project risk and cost. However, this model also requires expert personnel to be physically present for extended periods, which can be costly and limit flexibility. With a ping-to-cloud approach, processing and QC experts can now work from shore, applying advanced algorithms to analyze data in near real-time. This setup enables rapid detection of anomalies, data gaps, or system errors across multiple survey campaigns—without being tied to a single vessel or location. Rather than replacing onboard QC, this method extends capability by enabling distributed expertise and scaling the reach of your most experienced analysts. A single expert can now oversee multiple datasets across different platforms in a single day, dramatically improving resource efficiency and decision-making timelines.

Conclusion: Invest in Near Real-Time, Reap the Rewards

The offshore industry stands at a pivotal moment. The traditional, delayed approach to data processing is no longer sustainable in an environment where every minute and every Euro counts. Embracing near real-time underwater sensor data processing and immediate quality control through ping-to-cloud is not just an operational upgrade; it's a strategic imperative.

For offshore survey companies, utility operators, and TSOs, investing in solutions that provide near real-time insights means:

Saving hundreds of thousands, if not millions, of Euros by eliminating costly re-surveying

Don't let the high cost of hindsight dictate your offshore operations. Embrace the future of near real-time data analysis and transform your challenges into opportunities for unprecedented savings and success.

The Problem: Inefficiencies in Line Planning Are Costing You In offshore surveys, time really is money. Vessel operation costs can easily exceed...

The Challenge: Managing Data During Offshore Survey Operations Geophysical and hydrographic surveys generate vast amounts of data, requiring...

Introduction Wind farm projects, often stretching over 60, 100, and more square kilometers in ocean areas, are designed for 30 years of operations....

Building new offshore wind farms in a fraction of the time – Kiel-based startup creates smart marine data platform (MDP) for gaining high-speed...